MANUFACTURING PROCESS

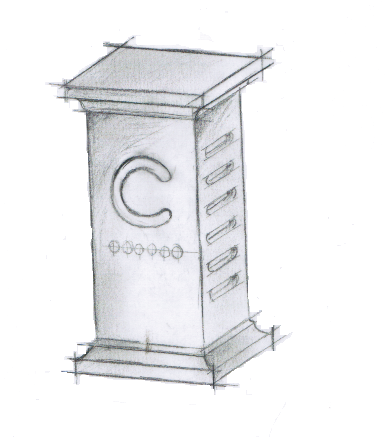

Step One : Sketching

To give form to the idea, it has first to be put down on paper. The initial, rough sketch is iterated to become, little by little, closer to a technical drawing with the main components and realistic dimensions.

Step Four : Finishing

It includes two operations where manual expertise prevails . A mechanical operation, which purpose is to smoothe the texture of the raw or machined surface : each part goes through processes such as polishing, sand-blasting or brushing. A chemical surface coating operation to color and protect the parts. Depending on the material, it can consist in typical industry processes such PLV , chrome plating or anodising… Special treatments can also be applied for specific requests.